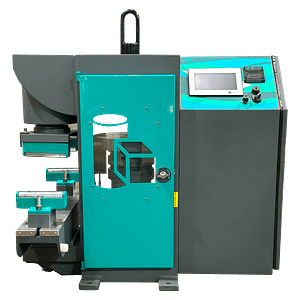

Description

6. Matt finished PU paint in dark color

7. Emergency stop push button

8. Safety lockable door

9. Hardened and grinded platens

10. Real-time graph for load vs time

11. Sample id, test id and lab id can be input onboard

12. Weight and age of specimen can be input onboard

13. 230 V AC, single phase motor

14. SCADA software available (at additional cost)

15. Meets the key specification of IS -516 & IS 14858 and other ASTM, EN and BS standard depending on platens and accessories chosen.

16. Actual pace rate display in KN/sec

17. Automatic stress determination and display.

18. Self aligning platen.

19. Data storage approx 10000 records on pendrive with graph in .csv/.jpeg format

20. Peak stress calculation based on sample type and shape.

21. No external PC or software needed, so simple to learn and use

22. 5% overload protection to calibrate the machine to full load

|

CAPACITY |

1000 KN |

200 TON |

300 TON |

|---|---|---|---|

|

RAM DIAMETER (MM) |

165 |

234 |

300 |

|

RAM TRAVEL (MM) |

50 |

50 |

50 |

|

PACE RATE (KN/SEC) |

1.0 TO 15.0 KN |

1.0 TO 15.0 KN |

1.0 TO 15.0 KN |

|

MOTOR CAPACITY (VOLTAGE) |

1 HP 230 V |

1 HP 230 V |

1 HP 230 V |

|

LEAST COUNT (IN KN) |

0.001KN |

0.001KN |

0.001KN |

|

MAXIMUM PRESSURE (Kgs./cm) |

480 |

480 |

600 |

|

PLATEN DIAMETER (MM) |

220 |

300 | 300 |

|

HORIZONTAL CLEARENCE (MM) |

260 |

320 | 380 |

|

VERTICAL DAY LIGHT (MM) |

310 |

310 |

310 |

|

HEIGHT OF LOAD FRAME (MM) |

770 |

890 | 990 |

|

WEIGHT APPROX (Kgs.) |

250 |

580 | 800 |

|

CUBE SPECIMEN (MM) |

50, 70.6, 100, 150 |

100, 150, 200 |

100, 150, 200 |

|

CYLINDER SPECIMEN (MM) |

100X200 |

100X200, 150X300 |

100X200, 150X300 |

Available Models:

1. Fabricated CTM Semi Automatic Model – 250 KN

2. Fabricated CTM Semi Automatic Model – 500 KN

3. Fabricated CTM Semi Automatic Model – 1000 KN

4. Fabricated CTM Semi Automatic Model – 2000 KN

5. Fabricated CTM Semi Automatic Model – 3000 KN

Reviews

There are no reviews yet.